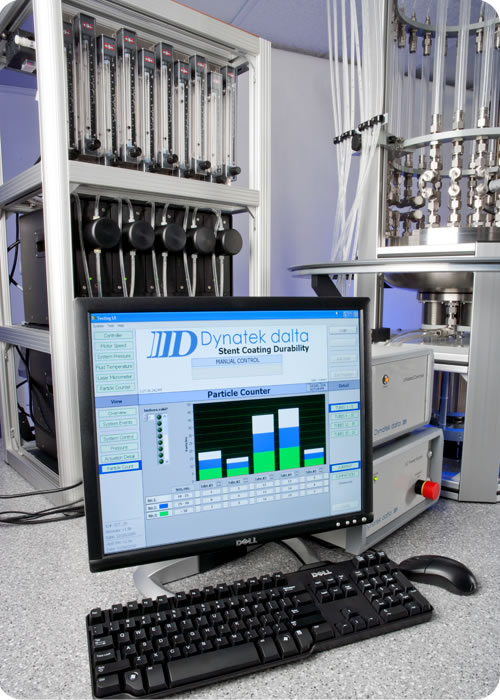

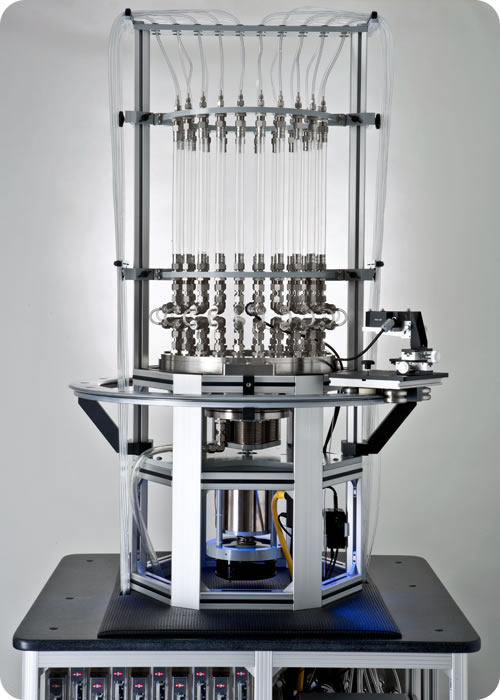

Dynatek’s patented1 Coating Durability Tester utilizes a Hyper Drive linear motor to produce an adjustable bellows compression which allows for physiologically relevant stent loading conditions for up to 20 test samples from physiological to accelerated testing rates of up to 150Hz.

Dynatek’s laser particle detection system allows accurate real-time counting, sizing, and data logging of shed particles from each drug-eluting stent during testing, giving a time course of shed particulates from each sample.

The large number of samples greatly benefits manufacturing QA when ongoing testing of approved stents is required.

CDT-20 Features and Capabilities

- FDA accepted with appropriate documentation.

- A master file on the machine is located at the USFDA.

- Compact integrated mounting stand or benchtop configurations available.

- Ability to test up to 20 samples simultaneously under precisely controlled test parameters.2

- Ability to test samples of slightly varying sizes of the same design at the same precisely controlled test parameters.

- Patented* system used to detect and identify, in real time, the number and size of shed particles from each sample.

- Integrated system has a smaller footprint than previous systems.

- Advanced universal controller with unmatched data collection ability.

- Data logging to a TDMS file which can be accessed by Excel or other software such as DIAdem and Matlab, for managing, analyzing, and reporting the test data collected.

- Unique redundant filtration system that allows for filter changes without test interruption.

- Frequency, temperature, and pressure controls give the user the ability to establish, maintain, and recall required test parameters.

- Ability to monitor sample tube pressures at all test frequencies.

- Closed loop laser micrometer feedback allows for automatic control and monitoring of mock artery distension.

- Long life electromagnetic Hyper Drive linear motor.

- Design allows for easy access to test samples.

- Universal controller allows for future expansion of the CDT-20 system to accommodate future host computer technology.

- Future upgrades with advance SCADA technology allow complete lab monitoring of all machines from a single host computer.

1US Patent # 7,621,192 B2

2Number of test samples dependent on diameter and compliance of sample tubes.

Available Add-ons

- Individual filters for each test sample.

- Various diameters of graft tube adapters for different test sample sizes.

- Custom modifications for the rack mount system.

- Valves to allow individual samples to be removed or replaced without interrupting the test.

- Very large diameter test samples possible with custom hardware.

- Alternative cap tanks and fluid heaters for higher test temperatures.

- UPS (Uninterruptable Power Supply) system.

- Adapters for catheter deployment of stents on the tester.

- Custom particle counter calibration for atypical particle size ranges.

- Custom collection filters available to aid in chemical analysis of particles.

- Other custom modifications at customer request.

- Learn more

- The Comprehensive Validation of a Stent Coating Durability Tester

- A Comprehensive Protocol and Procedural Considerations Designed …

- Particle Counters for Stent Testers

- SEM Analysis of Particles

- Compliant Silicone Vessels

- High Speed Photographic Verification of Stent Deflection

- Particulate Capture from Vascular Stents

- UC3-HD Controller

- Testing Standards relevant to the CDT-20

- ISO 12417-1:2015

- ISO/TS 17137:2014

- ASTM F2743-11

- ASTM F3036-13

- ASTM F2477-07

Cardiovascular implants and extracorporeal systems — Vascular device-drug combination products — Part 1: General requirements

ISO Link

Cardiovascular implants and extracorporeal systems — Cardiovascular absorbable implants

ISO Link

Standard Guide for Coating Inspection and Acute Particulate Characterization of Coated Drug-Eluting Vascular Stent Systems

ASTM Link

Standard Guide for Testing Absorbable Stents

ASTM Link

Standard Test Methods for in vitro Pulsatile Durability Testing of Vascular Stents

ASTM Link

Dynatek Labs Model CDT-20 Product Specifications

|

Description

|

Specifications

|

Additional Information

|

|---|---|---|

|

Number of test samples

|

20 test samples

|

20 test samples standard

|

|

Mock vessel configuration

|

Straight, curved, or bifurcated

|

Additional special configurations upon request

|

|

Mock vessel length (straight)

|

Adjustable

to ≤ 254 mm |

|

|

Mock vessel inner diameter

|

≈1.5 mm to ≤ 10 mm

|

|

|

Typical mock vessel compliance

|

5% to 7% per 100 mmHg

|

Other specifications available upon request

|

|

Testing rate

|

1.2 to 150 Hz

|

|

|

Testing fluid

|

PBS or distilled water

|

Other testing solutions possible

|

|

Fluid temperature

|

Ambient to ≤ 45⁰C

|

|

|

Flow rate

|

100 mL/min per sample

|

Per Lane

|

|

Test control parameters

|

Stent deflection (with high speed camera),

Tube deflection (with laser micrometer), Tube pressure (with pressure transducer) |

|

|

Laser micrometer

|

Solid-state laser diode (optional; 780 nm)

|

|

|

Pressure transducer range

|

0-10 psig

|

|

|

System fluid filter

|

0.2 micron

|

|

|

Particle capture filters

|

20 (optional)

|

1 common or up to 20 individual

|

|

Particle capture pore size

|

5 micron (optional)

|

Other pore sizes available

|

|

Controller

|

Universal Controller, featuring the NI™ Single-Board RIO platform

|

|

|

Software

|

Dynatek DAQ software based on LabVIEW architecture

|

|

|

Capacitance tank

|

1.5 gal

|

Dynatek Labs Model Particle Counter Specifications

|

Description

|

Specifications

|

Additional Information

|

|---|---|---|

| Number of particle counter modules |

20

|

Individual modules for each sample lane |

| Particle size range | 5-900 micron | Size and count up to 100 micron Count up to 900 micron |

| Particle count range | 15,000 p/mL @ 10 micron | |

| Particle bin range | 2-6 bins | 5 bins of 5-100 micron 1 bin for 100-900 micron |

|

Particle counter calibration standard

|

USP <788>, ASTM F658 | |

| Sizing resolution | 5-50 micron: +/- 1 micron 50-100 micron: +/- 5 micron |

Dimensions and Power Requirements

|

Module

|

Dimensions

|

Power Requirement

|

Weight

|

|---|---|---|---|

|

CDT-20 Integrated system

|

38”W x 40”D

x 94”H |

120 VAC 12 A

|

745 lbs.

(complete system) |

|

CDT-20 Bench Top system

|

60”W x 72”D

x 53”H |

120 VAC 12 A

|

600 lbs.

(complete system) |