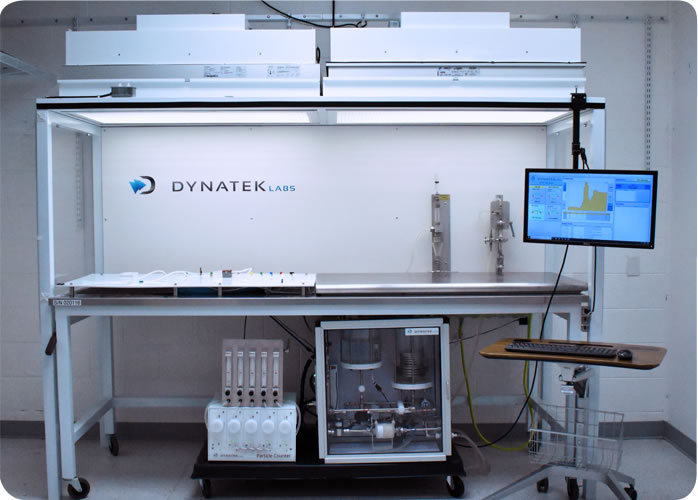

Dynatek’s patented1 Acute Particulate Tester leverages its world class particulate analysis technology for acute applications.

ASTM and ISO regulations drive the acute phase particulate testing of medical devices destined for use in the human vasculature. Acute Particulate Testing of vascular devices such as stents, stent-grafts, balloons, occluders, and delivery systems includes:

1. Particulate Matter Evaluation during Deployment and Withdrawal

2. Coating Integrity Inspection

Dynatek Labs provides a ‘one stop’ facility for your Acute Particulate Testing requirements.

1 US Patent # 9,453,788 B2

Particulate Matter Evaluation

FDA recommends that the device manufacturer is able to “demonstrate that the delivery catheter can safely and reliably deliver the stent to the intended location and that the stent is not adversely affected by the delivery catheter, both during deployment and withdrawal.”

Dynatek’s innovative Acute Particulate Testing platform includes a closed, temperature-controlled loop into which the vascular device is deployed, allowing the user to monitor particle shedding behavior in real time.

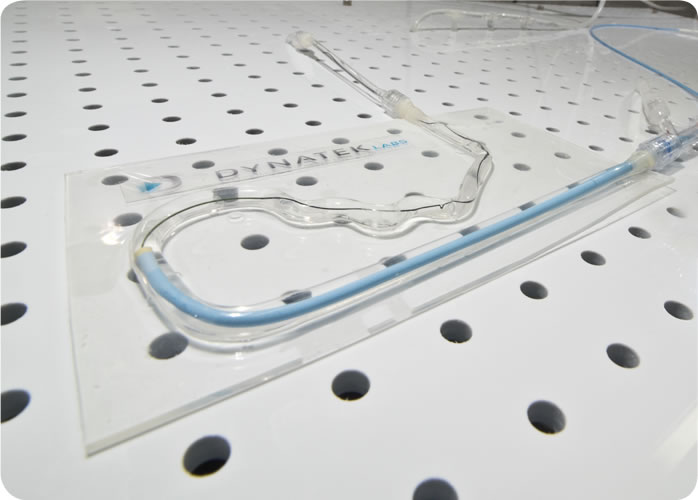

The vascular device is moved down this loop until it reaches the tortuous path, a section of the test tracking fixture that is described in ASTM F2394-07, or alternatively, a tortuous path furnished by the client. Particles shed by the device as it navigates the tortuous path flow directly into a debubbler and then through custom laser-based particle counters that both count and size particles into user-defined virtual bins.

Downstream of the particle counters, the particles are captured by optional particle capture filters, for SEM/EDX/FTIR analysis giving you critical information about the composition of the shed particles.

Dynatek can also have your stent or other device analyzed with SEM, furnishing you with SEM images that show the surface characteristics of the device both before and after acute particulate testing, as required by FDA regulations.

Clients may choose to perform this test at Dynatek’s testing lab; alternatively, Dynatek scientists can perform sample deployments, based on your protocol.

Drug-Eluting Balloon Testing

FDA considers drug-eluting balloons to be a hybrid product that combines an interventional device and a drug. Drug-eluting balloons are regulated by the Center for Devices and Radiological Health in collaboration in the United States with the Center for Drug Evaluation and Research as a Class III device. With our patented particle counting and particle capture technology, Dynatek Labs can assist you with answering crucial questions relating to how much of the coating on the balloon is shed as particles before and after balloon expansion, and the effect on the coating due to multiple expansions of the balloon and the consequent shedding of particles. The particles shed by the balloon can help evaluate the overall efficacy of the drug coating on the balloon.

Particulate Matter Evaluation during Deployment and Withdrawal

Particulate Matter Evaluation during Deployment and Withdrawal at Dynatek Labs references the following standards and regulations:

i. ASTM F2394-07 (2017) – Standard Guide for Measuring Securement of Balloon Expandable Vascular Stent Mounted on Delivery System

ii. ISO 25539-2:2012 – Cardiovascular Implants – Endovascular Devices – Part 2: Vascular stents

iii. FDA Guidance for Industry and FDA Staff – Non-Clinical Engineering Tests and Recommended Labeling for Intravascular Stents and Associated Delivery Systems, April 18, 2010

iv. FDA Guidance – Class II Special Controls Guidance Document for Certain Percutaneous Transluminal Angioplasty (PTCA) Catheters

v. ASTM F2743-11 – Coating Inspection and Acute Particulate Characterization of Coated Drug-Eluting Vascular Stent Systems

vi. AAMI TIR42:2010 – Evaluation of Particulates Associated with Vascular Medical Devices

vii. ASTM WK46148 – Standard Guide for Acute InVitro Evaluation of Drug Coated Balloons

viii. ISO 12417-1:2015 – Cardiovascular Implants and Extracorporeal Systems — Vascular device-drug combination products

ix. ISO/TS 17137:2014 – Cardiovascular implants and extracorporeal systems — Cardiovascular absorbable implants

x. ASTM F3036-13 – Standard Guide for Testing Absorbable Stents

xi. ASTM WK60510 – New Test Method for Simulated use testing of neurointerventional device in tortuous vasculature

xii. ASTM WK60511 – New Test Method for Particle evaluation and characterization for neurointerventional devices

Coating Integrity Inspection

Coating Integrity Inspection is normally carried out by an optical microscope or a scanning electron microscope under appropriate magnification. The stent is inspected before expansion, after expansion to its nominal or maximum diameter and after simulated use. Coating integrity inspection is performed to determine delamination or degradation of a vascular device during deployment. An affiliate lab performs all SEM coating integrity inspections for Dynatek customers, including a detailed report with images of defects, anomalies and artifacts found on the device surface.

Coating integrity inspection may organize coating defects and anomalies into several categories:

Category I – Anomalies related to coating thickness, which may be due to increased or decreased coating at any given point on the stent surface. Such anomalies may result in the exposure of bare metal in some areas or the formation of cracks, especially on the inside of curves or cause ‘blisters’ or ridges in the coating material

Category II – Non-homogenous coating may result in ‘wrinkle’ formation or ‘crater’ formation with or without metal exposure

Category III – Coating displacement may result in anomalies such as ‘webbing’ that may occur with or without metal exposure

- Testing Standards relevant to the APT

- ASTM F2394-07 (2017)

- ISO 25539-2:2012

- ASTM F2743-11

- AAMI TIR42:2010

- ASTM WK46148

- ISO 12417-1:2015

- ISO/TS 17137:2014

- ASTM F3036-13

- ASTM WK60510

- ASTM WK60511

Standard Guide for Measuring Securement of Balloon Expandable Vascular Stent Mounted on Delivery System

ASTM Link

Cardiovascular Implants – Endovascular Devices – Part 2: Vascular stents

ISO Link

Standard Guide for Coating Inspection and Acute Particulate Characterization of Coated Drug-Eluting Vascular Stent Systems

ASTM Link

Evaluation of Particulates Associated with Vascular Medical Devices

AAMI Link

Standard Guide for Acute InVitro Evaluation of Drug Coated Balloons

ASTM Link

Cardiovascular implants and extracorporeal systems — Vascular device-drug combination products — Part 1: General requirements

ISO Link

Cardiovascular implants and extracorporeal systems — Cardiovascular absorbable implants

ISO Link

Standard Guide for Testing Absorbable Stents

ASTM Link

New Test Method for Simulated use testing of neurointerventional device in tortuous vasculature

ASTM Link

New Test Method for Particle evaluation and characterization for neurointerventional devices

ASTM Link