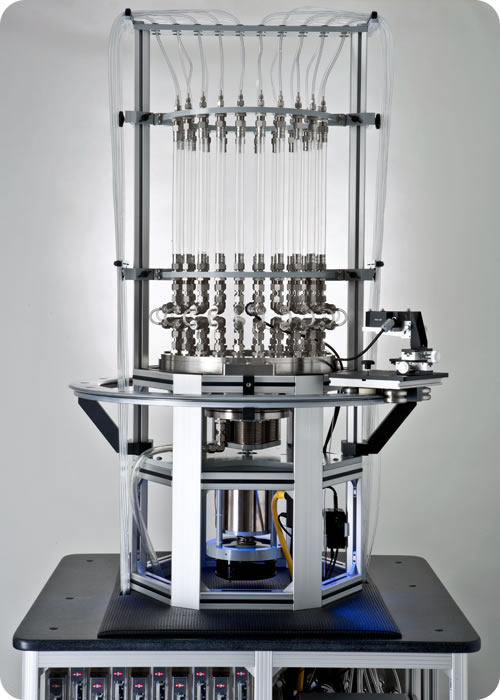

When a stent or stent graft is tested on the patented1 CDT-5 or CDT-20, it is tested for both pulsatile durability and coating durability simultaneously.

Coating durability of coated stents is evaluated using our custom-designed laser particle counters and membrane filter system, along with the associated software. This membrane filter system is located downstream of the sample stent. Particles shed by the coated stent first flow through the laser particle counter that enumerates and sizes particles from 7 to 1,000 microns. The particles then flow into the membrane filter system, where they are captured for further analysis that may include Scanning Electron Microscopy with chemical analysis of particles performed by Energy Dispersive X-ray (EDX) spectroscopy.

Counting, sizing and chemical analysis of the particles shed by the coating on your stent or stent graft provides critical data about the integrity and efficacy of the coating and its possible efficacy in vivo.

1 US Patent # 7,621,192 B2

Test platforms for coating durability:

Dynatek Labs performs radial pulsatile durability and fatigue testing, and bend testing of vascular stents and stent grafts compliant with the following standards:

ISO 25539-1:2017 – Cardiovascular Implants – Endovascular Devices – Part 1: Endovascular Prostheses

ISO 25539-2:2012 – Cardiovascular Implants – Endovascular Devices – Part 2: Vascular Stents

Guidance for Industry and FDA Staff: Non-Clinical Engineering Tests and Recommended Labeling for Intravascular Stents and Associated Delivery Systems; April 18, 2010

ASTM F2477-07 (2013) – Standard Test Methods for in vitro Pulsatile Durability Testing of Vascular Stents

USP General Chapter <788> Particulate Matter in Injections

AAMI TIR42:2010 – Evaluation of Particulates Associated with Vascular Medical Devices

ISO 7198:2016 – Cardiovascular implants and extracorporeal systems — Vascular prostheses — Tubular vascular grafts and vascular patches

Stent Migration

Bioabsorbable Stents and Polymeric Stents

For innovative devices such as polymeric or bioabsorbable stents, regulatory bodies tend to apply, at a minimum, the same tests and criteria that are used to evaluate drug-eluting stents unless the manufacturer can justify an exception to the applicable standard.

Normal durability periods of 400 million cycles may not apply to bioabsorbable stents that are absorbed in the body in 12-24 months. However, coating durability tests to evaluate particle generation by the stent coating and possibly by the stent itself, due to its inherent ability to undergo degradation in a fluid environment, should be performed as part of regulatory submissions.

Dynatek Labs can also perform customized tests to evaluate the rate of degradation of bioabsorbable stents over time.

Testing to Success and Testing to Failure

Durability testing up to 400 million cycles is often called ‘testing to success,’ since stents that have successfully withstood the stresses and strains of 400 million cycles are understood to have passed the test. Testing to success is indicative of the durability of the stent under physiological conditions of systolic/diastolic pressures encountered in accelerated radial pulsatile durability testing. However, testing to success does not predict the endurance limit or fatigue life of the stent, i.e., there is no way to know under what conditions, including conditions that may exceed physiological parameters, the stent or stent graft would fail.

To address this weakness, new regulations outline test requirements that are now concerned with predicting fatigue lifetime of the stent or stent graft and require stent manufacturers to test their products under a ‘testing to failure’ or ‘test to fracture’ regime. The 2010 FDA Guidance Document recommends that stents and stent grafts be tested up to their ‘endurance limit,’ and ISO requires the implant to be tested under ‘a worst-case physiological load.’ While ISO does not require manufacturers to test implants under conditions that may exceed physiological conditions, the FDA’s testing to failure recommendation has no such restriction.

Dynatek Labs has radial pulsatile durability testers that can test stents and stent grafts under testing to success and testing to fracture regimes. According to ASTM and ISO, the best way to define the fatigue life of an implanted device is to combine appropriate stress/strain analysis with tools like finite element analysis (FEA) combined with physical test to failure or test to fracture. We have in-house protocols for durability testing and testing to fracture, and we would be happy to either work with your test protocol or develop one for you based on your requirements.

Protocol for durability testing:

Dynatek Labs has standard protocols for testing your vascular stent, based on the standards and regulations listed above. However, we routinely create custom protocols for specific requirements for virtually any vascular device and would be happy to develop a custom protocol for you.

Dynatek Labs fabricates our own silicone mock vessels to meet FDA requirements and ISO 7198 regulations. We fabricate the most accurate and consistently precise mock vessels needed for your durability testing, and these vessels can be straight, curved, bent, bifurcated or completely custom per your specifications.

Test Monitoring and Reports

Dynatek offers visual inspections, as well as still, and optional video and high-speed photography during pulsatile durability and coating durability testing of stents and stent grafts.

All testing, inspections, monitoring and reporting are GLP-compliant. Dynatek’s test reports are detailed and comprehensive documents that can be directly submitted to regulatory agencies and typically include the following sections:

- Executive Summary

- Scope

- Methods and Materials

- Sample Description

- Test Parameters

- Observations

- Results

The report also contains a copy of the actual protocol used to run the test, sample photographs and tester photographs, and copies of relevant certificates of calibration of sensors used on the test platform. In addition to a hard copy of the report, we also include a complete digital version of the same material on a CD and ship it to you.

For more information on pulsatile durability and coating durability testing at Dynatek Labs, click Contact US button below.