Why Fatigue to Fracture is needed

Current regulatory standards require testing to success for the intended lifetime of the device. In addition to this requirement, device manufacturers have long sought to bolster their safety data by exploring the endurance limit of their products. Properly executed FtF testing can predict the lifetime of your product. It can also identify locations of future failure and verify Finite Element Analysis (FEA) predictions.

Dynatek Labs offers a real solution

This instrument is the latest in a series of historic contributions that Dynatek Labs has been responsible for over the past 40 years. Building on the well-established fundamentals of fatigue to failure, Dynatek’s patented1 FtF tester is a unique and effective solution to evaluate predictory Fatigue to Fracture (FtF) testing of vascular stents, endovascular prothesis, and other tubular elements. Leveraging our decades-long expertise developing radial fatigue testers, Dynatek has further enhanced the experience by offering a robust instrument capable of delivering hyper-physiological pressure excursions, paired with visual monitoring of samples to pinpoint the precise moment and location of fractures.

1 US Patents # 10,627,315 B2; # 10,605,700 B2

Testing Advantage

A properly designed and executed Fatigue to Fracture evaluation can predict:

1. Endurance limits by varying the load, frequency of test, temperature or pH

2. Predict potential failure locations of the device

3. Verify (or not) the validity of a Finite Element Analysis

- Learn more

- The Durability Testing of Porous Bifurcated Stent/Grafts …

- The High Frequency Testing of Vascular Grafts and Vascular Stents: Influence …

- Sources of Error in Monitoring High Speed Testing of Vascular Grafts

- Design Considerations for the In Vitro Testing of Cardiovascular Prosthesis

- High Speed Vascular Graft Testing: The Influence of Varying Structural…

- Compliant Silicone Vessels

- High Speed Photographic Verification of Stent Deflection

- UC3-HD Controller

FtF Features

- Extremely strong stainless manifold capable of 2000 mmHg cyclic loading

- Unique bellows design with up to 1 billion cycle lifetime

- Components capable of withstanding up to 60 °C temperature and pH 12.0

- Custom designed electromagnetic motor that delivers years of continuous service

- Specialized mock vessel envelopes to facilitate realistic response at hyper-physiological pressures

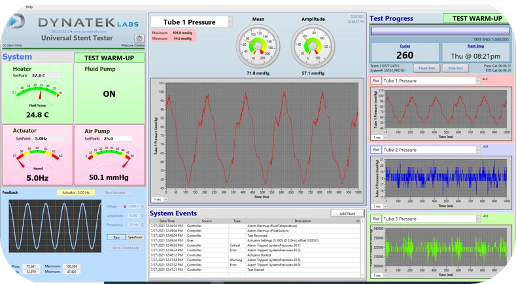

- Continuous monitoring of temperature, cycle, frequency, and relevant pressures

- 360-degree visual monitoring across all samples for precise identification of fractures

Sample adapters with pneumatic distal manifold assembly.

Software

DynUC Universal software controls and monitors all experimental parameters and records them as frequently as once per minute. All parameters are automatically written to a secure datafile. Tandem camera software provides visual verification of fractures with precise time-stamps to correlate cycle count.

As you can see in the photos, the Dynatek Fatigue to Fracture tester is an impressive, strong and powerful instrument. Not just built for endurance testing, it includes a safety enclosure that ensures operator safety.

The second part of the story is focused on the unique mock artery system that we have developed. By using a combination of outer and/or inner mock vessel you can:

1. Produce agressive contraction only loading

2. Produce agressive expansion only loading

3. Produce agressive expansion and contraction loading

The Dynatek Fatigue to Fracture tester is a unique and effective way to carry out predictory Fatigue to Fracture testing on vascular stents, endovascular prothesis (or other tubular elements that may not be a medical device). This instrument is the latest in a series of historic contributions that Dynatek Labs has been responsible for over the past 30 years.

Dynatek personnel will custom design any protocol or instrument to meet your needs.

Dynatek Labs FtF Product Specifications

|

Description

|

Specifications

|

|---|---|

|

Number of samples

|

≤ 10 |

|

Sample diameter

|

1-10 mm ID

|

|

Sample length (straight)

|

≤ 250 mm

|

|

Sample configuration

|

linear for easy photography |

|

Manifolds

|

stainless steel, proximal and distal

|

|

Temperature range

|

room temp to 60 °C |

|

pH range

|

5.0 to 12.0

|

|

Systemic pressure

|

up to 28 psi

|

|

Control system

|

Dynatek’s Universal Controller

|

|

Variables controlled and/or monitored

|

temperature, cycle rate and count, systemic pressure, sample pressure(s), visual fracture detection

|

|

Certification

|

CE mark

|

|

Data poll interval

|

≥ 1 min

|

|

Power requirements

|

120/240 V 50/60 Hz

|

|

Test samples of various dimensinos

|

yes

|

|

Unattended operation

|

yes

|

Specifications are subject to change without notice.