Introduction

Radial fatigue testers and coating durability testers both use stent samples mounted in mock silicone vessels for chronic fatigue and durability testing. While all testers feature pulsatile pressurization, some also have ‘flow-through’ capabilities.

Non Flow-Through Testing

Stents undergoing testing need to experience pulsatile pressurization at a uniform temperature. To pressurize the mock vessel and the device deployed inside it, a test solution (e.g., a buffer like phosphate buffered saline) is used.

When a non flow-through instrument is used to pressurize the mock vessel and stent, the fluid flows into the proximal end of the mock vessel, fills it up and pressurizes it in a pulsatile fashion, without the fluid in the mock vessel flowing out the distal end of the vessel. The fluid in the non flow-through method of testing is at a known temperature and therefore it is assumed that the stent is at, or close to, that temperature.

The reality, though, is that since the mock vessel is closed at one end, the temperature across the length of the vessel and the stent is not uniform, with the temperature falling the further you go from the vessel’s proximal end. This temperature gradient occurs because there is little or limited mixing of the solution inside the mock vessel. The larger the mock vessel/stent construct, the greater the temperature gradient, as much as 12°C in competitive instruments.

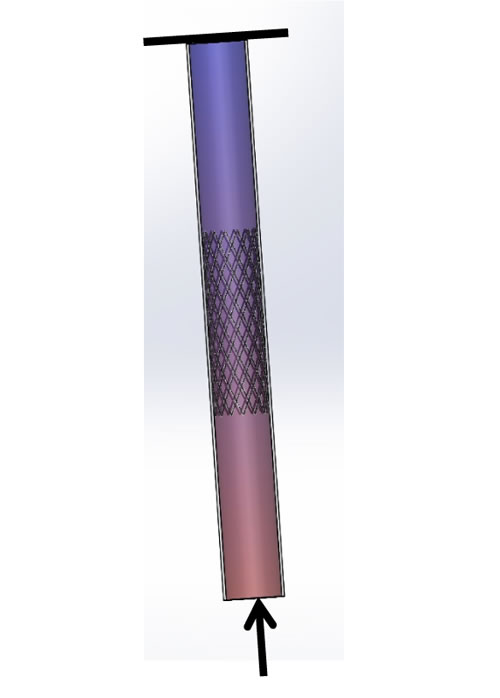

In Fig. 1, fluid moves into the proximal end of the mock vessel (see arrow), to deliver pulsatile pressurization. The upper end of the vessel is closed off. The red color represents fluid that is close to the actual desired temperature, which cools as you go further along the vessel (shown by the blue region).

Fig 1: Static pressurization

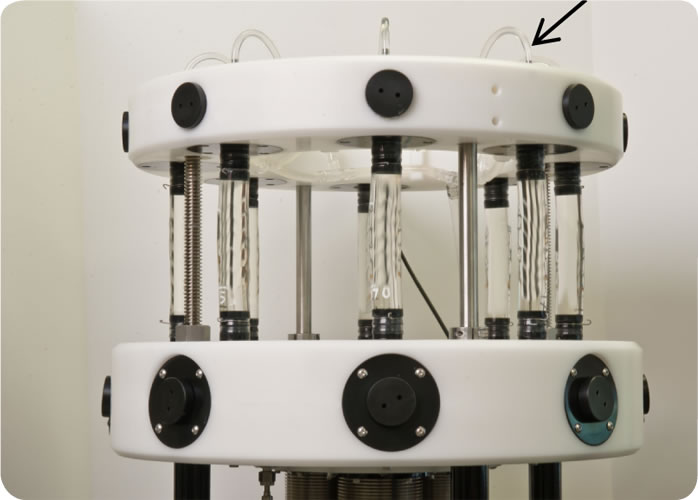

Fig 2: Flow-through pressurization

Flow-Through Testing

In Fig. 2, fluid moves into the proximal end of the mock vessel with the stent deployed in it, and out the distal end (see arrows).

Here, since fluid at a known temperature is moving through the mock vessel containing a stent, delivery of new heated fluid inside the mock vessel occurs and the stent is maintained at the temperature of the fluid.

This is indicated by a uniform red color throughout the mock vessel/stent combination in the figure above.

Regardless of the length or diameter of the mock vessel, the temperature inside the vessel is uniform, unlike when the fluid is not moving through the mock vessel. Thus, flow-through is critical for obtaining uniform temperatures across the mock vessel/stent combination.

Particulates and Flow-Through

When a coated stent is undergoing durability testing, it is especially important that the mock vessel containing the coated stent undergoes flow-through during testing. Flow-through with a coated stent allows the stent to shed particles which are continuously removed from the mock vessel and these particles can be counted and analyzed or just filtered/captured downstream of the mock vessel.

Without flow-through, the fluid does not completely exit the mock vessel, and particles that are shed by the stent accumulate inside the vessel, possibly leading to further erosion by abrasive contact between these accumulating free particles and the intact coating of the stent.

Drug-eluting, Polymeric and Absorbable Stents

Flow-through testing is also important for durability testing of drug-eluting, polymeric and absorbable stents. The controlled release of a drug is critical to the function of drug-eluting stents, and in a flow-through environment, the actual rate of elution of the therapeutic agent can be analyzed, since there is no accumulation of the therapeutic agent inside the mock vessel. Similarly, with an absorbable stent, the dissolution of the stent is not impeded by accumulating solute in the mock vessel.

Conclusions

When testing uncoated, drug-eluting, polymeric or absorbable stents, it is important to ensure that:

a. Temperature of the stent is uniform across its entire length

b. Particles shed by the stent do not accumulate inside the mock vessel, and

c. Solutes shed by therapeutic agents do not impede further dissolution of the therapeutic agent

Dynatek Labs’ radial fatigue testers such as the SVP/UST Testers and coating durability testers such as the CDT-5 and CDT-20 all feature flow-through capabilities that are designed to ensure uniform temperatures across the entire stent, remove released debris, and ensure test conditions that best emulate the in vivo environment. Competitive machines try to retrofit flow through but this has been shown to be ineffective. Dynatek machines were designed from the beginning to possess flow through technologies.