The Design, Fabrication and Characterization of Mock Latex…

Silicone Mock Arteries

by | SFB 1998 | Publications, Silicone Mock Arteries

The Design, Fabrication and Characterization of Mock Latex Aorto-Iliac Bifurcations

J.C. Conti1, E.R. Strope, D. Rohde, K. Price, and S. Kulan

Dynatek Dalta Scientific Instruments

1 Southwest Missouri State University

SFB 1998

Introduction

Mock arteries made of latex or other materials greatly aids the development of medical products in that certain durability and performance characteristics can be determined in vitro. It is critically important, however, that the dimensions and three-dimensional mechanical properties of these devices be precisely known. Up until now, we have been unable to design aorto-iliac bifurcations to be used in the in vitro testing situation that could be evaluated both at real time or at accelerated rates. The problems are related to the errors associated with laser and ultrasonic measurements or the averaging techniques necessary for internal volume displacement techniques on tapered bifurcations.

Purpose

The purpose of this work was to design a mock aorto-iliac bifurcation that could be precisely characterized with respect to its internal compliance at various testing frequencies.

Material and Methods

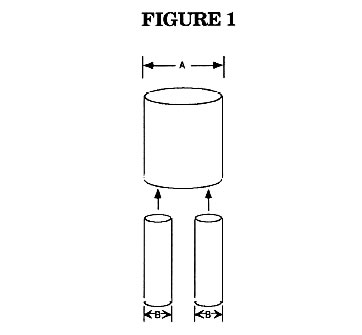

A three part mold was developed as indicated in Figure 1. This mold was used to make non-tapered sections of the aorto-iliac bifurcation such that the individual components of the mock artery could be isolated and independently tested. Several different wall thicknesses were used in the fabrication of a series of devices and Table 1 shows results of various diameters of the aortic or iliac components versus the radial compliance.

Results

The wall thickness versus compliance relationships suggest the need for a complex dipping procedure that would result in different wall thicknesses for the aortic versus iliac components. We are currently in the process of testing the full device. We predict that the resultant average compliance of the device would be 5 to 7%. Results will also be available from a comprehensive evaluation of internal radial and longitudinal compliance versus testing frequency.

| Table 1 | |||

| Diameter (mm) | Wall thickness (in.) | Percent Radial Compliance1 | |

| Aortic (A) | 29.81 | 0.131 | 6.15 |

| 36.45 | 0.145 | 5.51 | |

| Illiac (B) | 14.50 | 0.074 | 5.35 |

| 17.53 | 0.081 | 6.88 | |

| 1 Measured at 72bpm over a pressure excursion of 80 to 120mmHg normalized to 100mmHg differential. |