Test Sections for the M6 Heart Valve Tester

Introduction

Dynatek’s M6 Heart Valve Tester uses test sections that are specially designed to securely hold replacement heart valves of all types for accelerated wear or durability testing.

Test Section Fabrication

When you request a quote for an M6 Heart Valve Tester or a quote for testing your heart valve candidate, Dynatek will include a line item for a set of six custom test sections.

Our engineers first make drawings of the custom test sections based on the heart valve candidate that you send us. Drawings are made in SolidWorks, and save valuable time by allowing any required changes to be made speedily. As the design of your heart valve may undergo changes during its development phase, SolidWorks drawings allow us to quickly and efficiently modify the design of your test sections where needed.

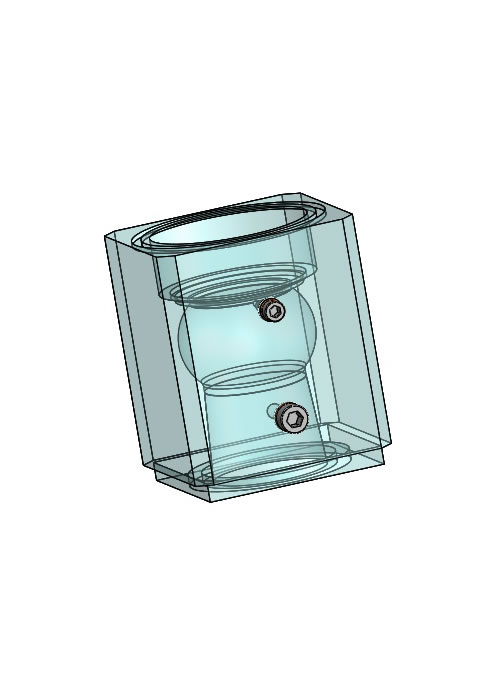

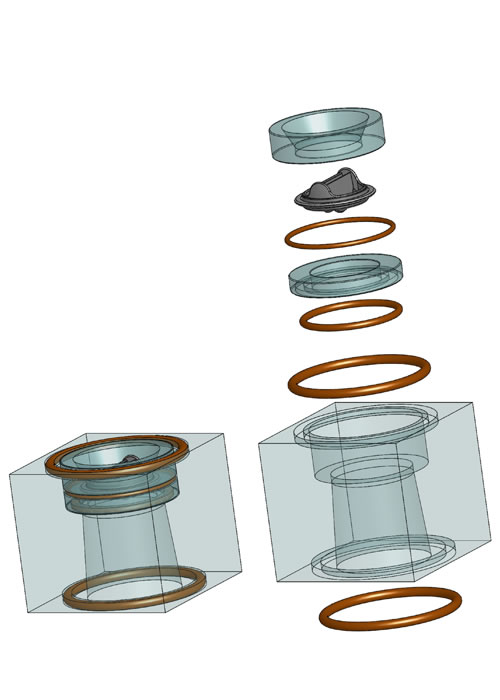

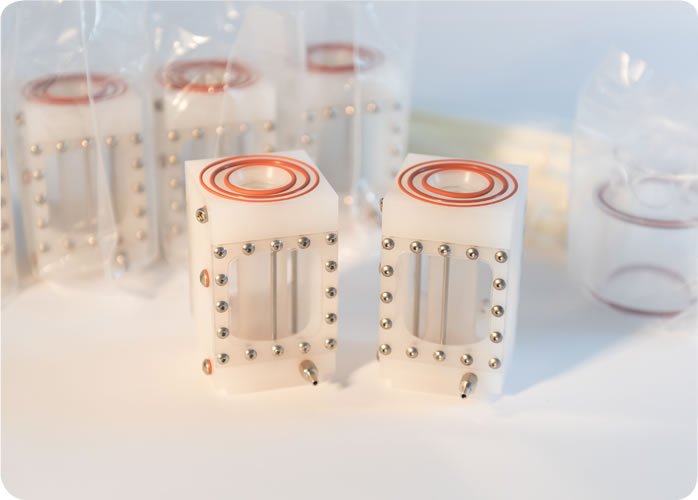

Test sections are normally made of acrylic or polycarbonate. Both of these materials are highly amenable to fabrication by CNC machines. CNC machining allows us to fabricate test sections with intricate shapes and ultra-tight tolerances. Many test sections feature ports, O-rings, gaskets and other fittings, and CNC machining allows more precise drilling, boring, thread milling and reaming operations on our test sections to provide such fittings.

Final finishing normally includes vapor polishing, which produces a crystal clear, glass-like finish. Vapor polishing and the square cross-section of the test section allows excellent visualization of the test valve from four sides and helps in still or video photography during testing.

Test Section Types

Custom test sections can be made for mechanical, tissue, stentless and percutaneous heart valves and for testing biomaterials. Percutaneous heart valve durability testing.

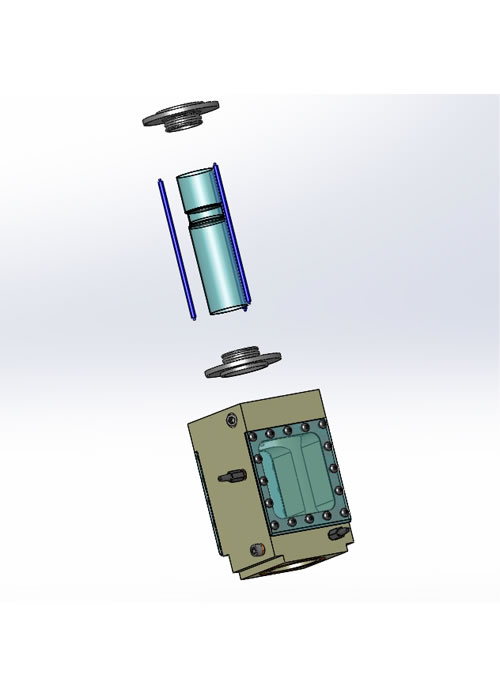

Fig. 1 shows a custom test section for stentless or catheter delivered valves.. Such test sections may feature metal parts, screws, plates, and gaskets.

Fig. 2 shows a custom test section featuring user-specified ports for a tissue valve.

Some test sections may require compliant mock vessels for mounting and/or sewing the heart valve to a support that mimics the in vivo structure in the heart. Dynatek has been fabricating compliant silicone mock vessels for 27 years and our experience with mock vessels is unparalleled.

Testing Heart Valves

The M6 Heart Valve Tester can test up to six heart valves at a time, each valve deployed in a single test section.

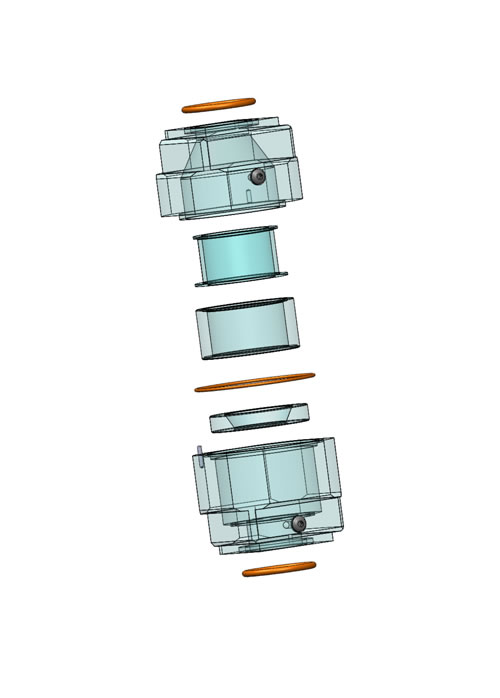

Two or three different sizes and/or types of heart valves may be installed simultaneously, if the appropriate test sections are used, and similar pressures are obtainable. When running different valve types, each pair of identical valves are located diametrically opposite to each other on the M6.

It may also be possible to run two sizes of valves in the same size test section on the M6, with the use of appropriate O-ring adaptors.