Relating the Frequency Dependent Radial Compliance to the Tensile …

Mock Artery Compliance

by | SFB 1996 | Publications, Compliance

Relating the Frequency Dependent Radial Compliance to the Tensile Modulus of Polyurethane Vascular Grafts

5th World Biomaterials Congress, Transactions Volume 2, 434, (1996)

Bozzi, R1, Conti JC, Rohde D, Soldani G1, Spence L, Strope E, and Withrow D

Dynatek Dalta Scientific Instruments, PO Box 254, Galena, MO 65656

1 Instituto di Fisiologia Clinica, Via Trieste 41, 56126 Pisa, ITALY

SFB 1996

Introduction

Since first introduced as a biomaterial in 1967, (1) polyurethanes have been utilized as candidate materials for vascular grafts. They show a high degree of toughness combined with a tendency to be blood compatible. It has been suggested that compliance matching of vascular grafts to recipient vessels is important to long term patency. (2)

Polyurethane materials are susceptible to calcification, enzymatic degradation and autooxidation (3). There is a large number of polyurethanes that could be candidate materials for vascular grafts and, coupled with tunable manufacturing processes, could produce an effective long term implant. The problem is to evaluate a large number of materials in a timely and cost effective manner.

It is our intention to develop a three-part series of tests that will give biomaterial scientists and engineers a well-defined procedure to screen candidate materials for mechanical acceptability.

This report represents the results of our first evaluation towards this goal. In this study we compare the frequency dependent radial compliance of intact polyurethane and latex vascular grafts to the frequency dependent tensile modulus obtained from circumferential samples of the same graft.

Materials and Methods

Two polyurethane vascular grafts were prepared and supplied according to the technique of Soldani et al (4). The difference in these grafts represented a slight variation in the angle at which the polyurethane was deposited on the receiving mandrel. Both of these grafts were subjected to dynamic internal compliance testing. The radial compliance was evaluated over the pressure excursion from 80 to 120mm Hg at testing frequencies of 72, 200, 400, 600, 800 and 1000 cycles per minute.

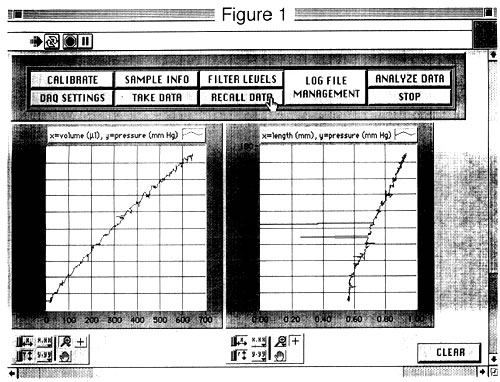

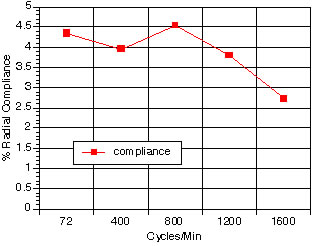

Three latex grafts were manufactured using a custom dipping process that allowed for somewhat predictable radial compliance. The actual radial compliance (Figure 1 attached) was determined over the pressure excursion from 80 to 120mm Hg at testing frequencies of 72, 400, 800, 1200, and 1600 beats per minute.

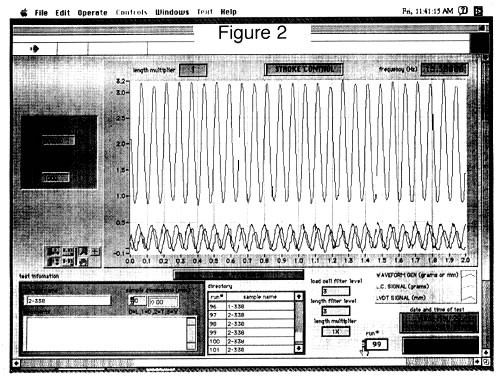

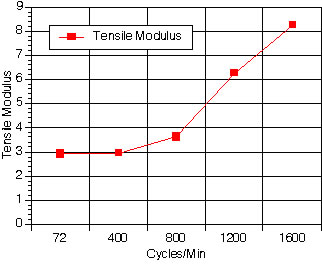

Three 4mm wide hoops were then cut from different regions of the graft samples. These hoops were split and mounted on a dynamic micromechanical tensile tester. The tensile modulus of these samples was then evaluated at the same cycle rate and strain that the compliance was determined (Figure 2 attached).

Figure 1

Figure 2

All samples were dabbed with distilled water to keep them moist throughout the testing.

Results

Radial Compliance (PU)

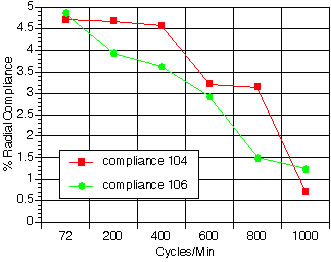

Figure 3

Figure 3 is a summary of the percent radial compliance determined at the various speeds for each polyurethane sample. There is a general trend to have reduced compliance with increased test frequency, which is to be expected. Also note that the largest changes in sample 104 occur when going from 400 to 600 beats per minute and again from 800 to 1000 beats per minute. With sample 106 the largest changes occur at the transition from 72 to 200 beats per minute and from 600 to 800 beats per minute.

Tensile Modulus (PU)

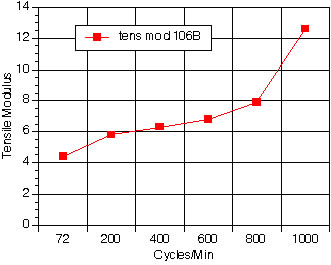

Figure 4

Figure 4 shows the summary of the tensile modulus, here calculated as the simple slope of the stress-strain curve. The variation from sample to sample is quite striking. Some of the frequency dependent transitions in modulus correspond to the same transitions seen in the compliance data. The trend seems to suggest that the dynamic mechanical properties of the graft are influenced by the fact that they have been shaped into a tube and not just by the properties of the polyurethane.

Radial Compliance (Latex)

Figure 5

Figure 5 shows the radial compliance of the latex tubes versus testing frequency. Here the most dramatic reduction in compliance occurs when increasing the frequency from 1000 to 1600 cpm.

Tensile Modulus (Latex)

Figure 6

Figure 6 displays the corresponding tensile modulus data. As with the polyurethane grafts, the frequency at which onset of increased stiffness occurs is lower with the strip samples.

Conclusions

Radial compliance versus frequency information is commonly used to determine the maximum effective test speed when performing accelerated durability testing on vascular graft or stent samples. The modulus versus frequency that we have presented here support the position that changing the structure of the vascular graft while keeping the materials the same can have an influence on the dynamic properties of the resultant device.

We are currently evaluating the hysteresis properties of these samples and will correlate the above compliance and modulus results with hysteresis and eventual accelerated durability of the whole grafts.

References

1 Boretos, J.W., Pierce, W.S., Science 158:1481 (1967)

2 Abbott, W.M., Cambria, R.B., “Control of Physical Characteristics of Vascular Grafts” Biologic and Synthetic Vascular Prosthesis Ed. J.S. Stanley, Grune and Stratton, 1982, 189-219.

3 Stokes, K., Coury, A., Urbanski,P., “Autooxidative Degradation of Implanted Polyether Polyurethane Devices”, J. Biomat. App., 412-448, 1987.

4 Soldani, G., Panol, M., Goddard, M., Sasken, H.F., Galletti, P.M., J. Mat. Sci.: Materials in Medicine, 3:106, 1992.