Introduction

Stents and stent-grafts are routinely tested in vitro by deployment in silicone mock vessels. Accurate radial fatigue testing of these vascular devices depends on two factors:

a. The frequency response characteristics of the mock vessel and device, and

b. A consistent cyclic load applied by the mock vessel on the device.

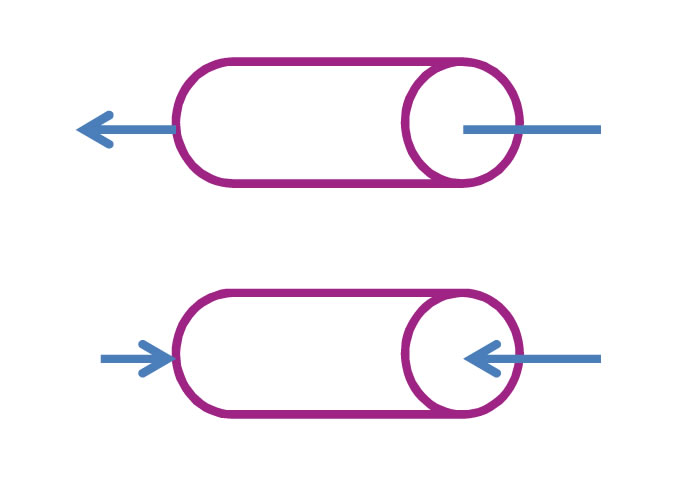

Cyclic load is transmitted uniformly to the device only if the mock vessel undergoes symmetric expansion around its entire circumference with every load cycle. For consistently accurate radial fatigue testing of stents, it is critical that all points on the entire length of the mock vessel that contains the stent or other device undergo the same deflection and cyclic load with every pulse. There are two ways you can transmit a cyclic load to a stent deployed inside a mock vessel: pressurization from one end (single-ended) or pressurization from both ends of the mock vessel (double-ended), as shown in Fig. 1. Single-ended and double-ended pressurization have distinct vessel expansion patterns, and the cyclic loads in these regimes are different, as explained below.

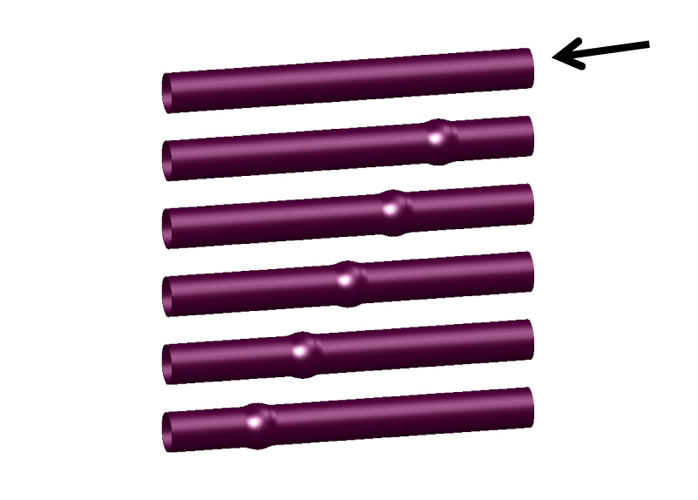

Single-Ended Pressurization

When pressure is directed from one end of a mock vessel with a stent deployed inside it, the pressure pulse moves from one end to the other (see Fig. 2). In Fig. 2, the pressure pulse moves from the right to the left of the mock vessel, and is depicted as a bulge or bolus in the tube, starting from the tube at the top. As the pressure pulse moves from right to left, it traverses the entire length of the stent. In the single-ended pressurization regime described here, the pressure pulse moves down the length of the mock vessel and stent. Every point of the mock vessel and stent will undergo the same cyclic load and deflection that the preceding point has undergone (assuming a uniformly compliant mock vessel).

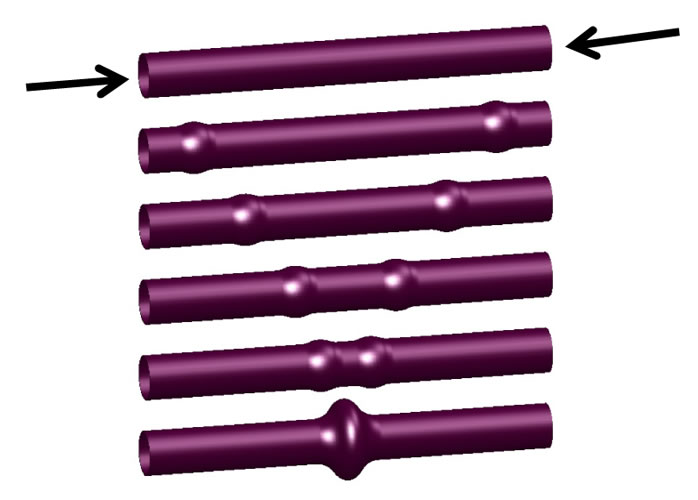

Double-Ended Pressurization

In Fig. 3, the pressure pulse moves into the mock vessel with the stent deployed in it from both ends. As the pressure pulses move towards the center of the mock vessel, the mock vessel and the stent undergo deflection. As the two pressure pulses approach the center of the mock vessel, they meet, undergoing ‘constructive interference.’ The deflection caused by the resultant load is the sum of these pulses. If the stent was centered in the mock vessel, then the central part of the mock vessel along with the stent would undergo a significantly higher deflection than any other part of the stent.

Conclusion

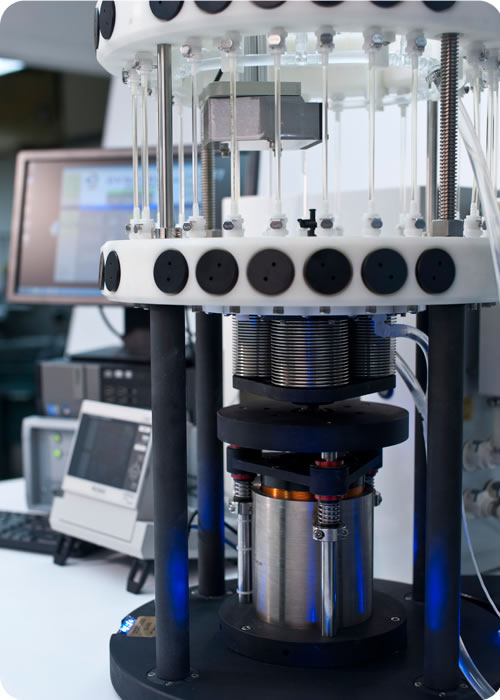

Radial fatigue testing of stents and stent-grafts depends upon even expansion and uniform cyclic loading of the mock vessel/stent combination. Such conditions are consistently obtained when the sample is pressurized only from one end. When the sample is pressurized from both ends, constructive and destructive pressure pulses cause uneven cyclic loads and nonuniform sample deflections, leading to inaccurate and inconsistent results. In addition, even very small cycle-to-cycle variations in either motor can move the location of the constructive interference, thereby varying the location of the maximum stent deflection. Dynatek’s radial fatigue testers and coating durability testers pressurize the sample from one end only, offering highly accurate and consistent radial fatigue results.

Reference

Single Versus Double-Ended High Frequency Pressurization of Mock Arteries: Symmetry of Expansion. Ramesh, R., Conti, J.C. and Strope, E.R. Biomedical Science Instrumentation, 42, pp. 446-451, (2006).